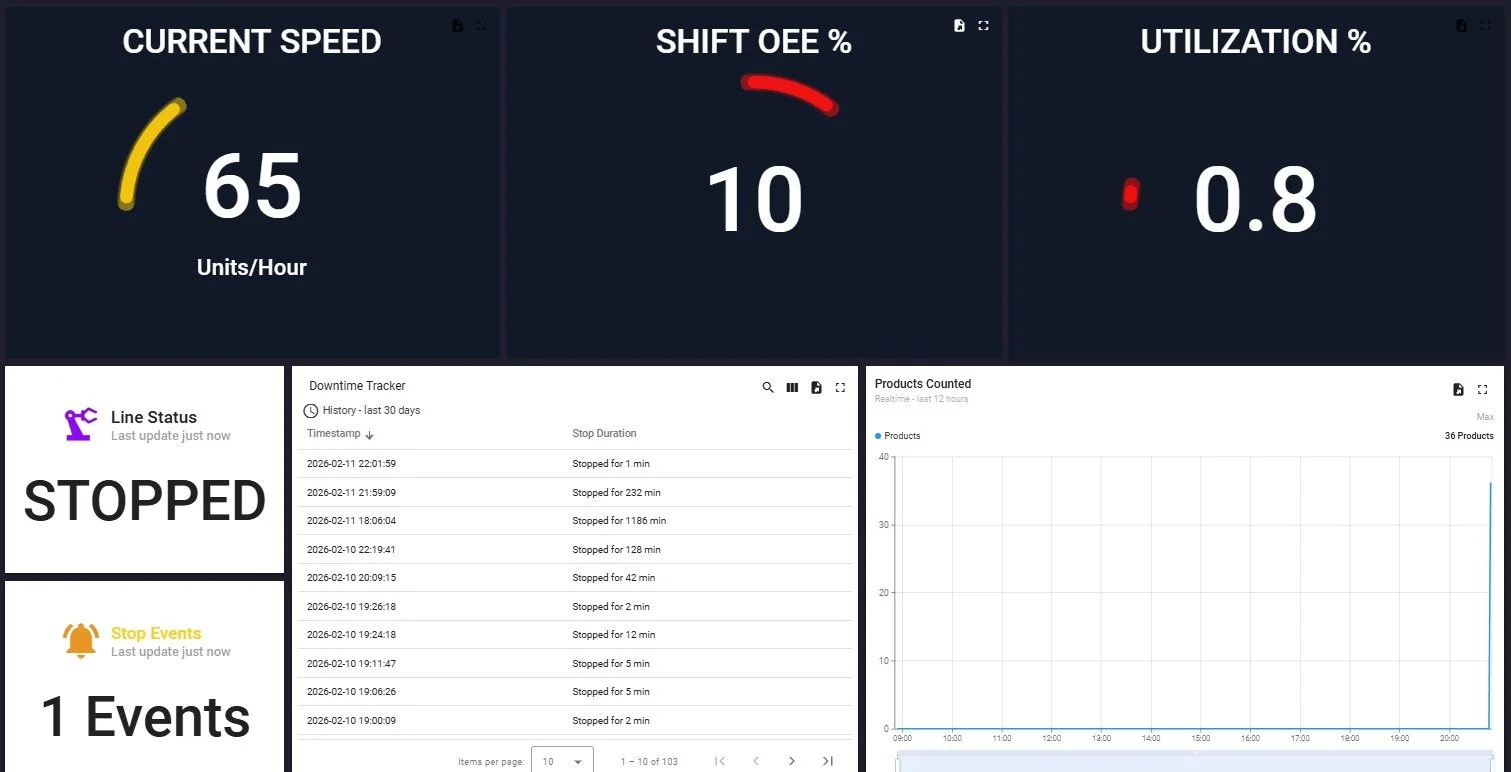

Eliminate downtime and maximise OEE.

Turn any legacy production line into a

"Smart Line" in 5 minutes.

Live data from factory in your pocket

Viewable instantly on Phone, Tablet, or Office PC

-

See exactly what is being produced now, not at the end of the shift.

-

Is the line running at 100% capacity or limping at 80%? Spot micro-stoppages and slow-running lines instantly.

-

Compare Day vs. Night shifts with zero paperwork.

The 3-step installation

We don't touch your PLC. We don't touch your wiring.

1.CLAMP: Our industrial-grade bracket fits any standard conveyor rail or T-slot frame.

2.POWER: Plug the unit into a standard 240V socket. No complex cable routing or panel building.

3.CONNECT: Securely join your site Wi-Fi to push live data to your private Cloud Dashboard.

Join the West Midlands Pilot Program

We are a Birmingham-based engineering team launching the first production batch of the Async Gen-1. We are currently seeking 3 Manufacturing Partners in the West Midlands to join our exclusive pilot phase.

The Pilot Package inclues (£150)

1x Async Gen-1 Hardware Suite (High-precision Sensor + Clamp).

Full Dashboard Ecosystem (30 days of access to the dashbaord).

Performance Guarantee: If you don't find actionable efficiency gains within 30 days, we’ll refund you.

Register here: